Continuing with the engine, I decided to take the oil pump off to inspect it and clean it up. I'm glad I did because I found a lot of sludge built up inside. I took it apart and noticed that the spring was broken and it needed a new gasket. All gears and bushing were in excellent shape! Washed the screen with varsol!

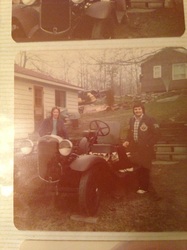

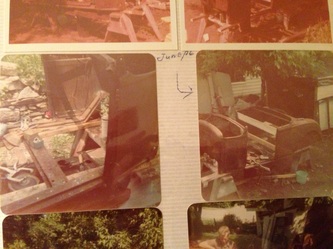

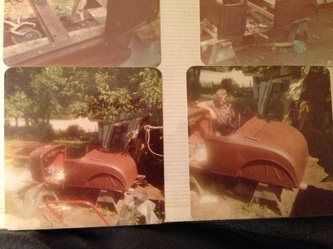

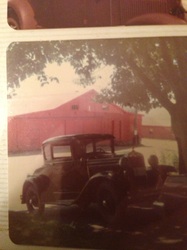

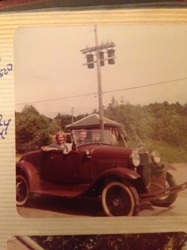

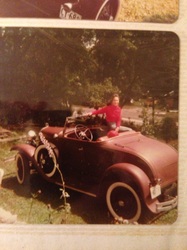

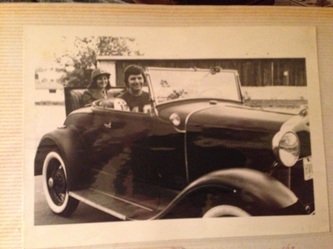

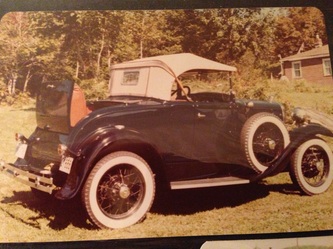

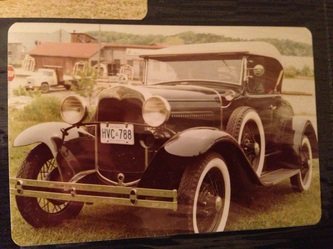

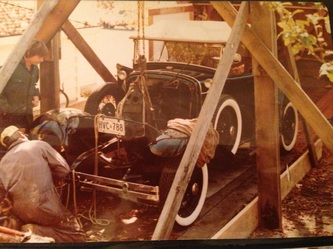

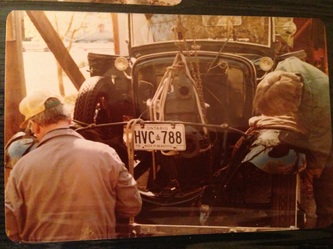

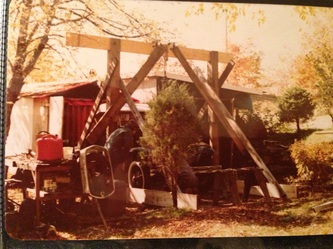

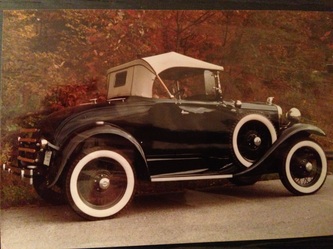

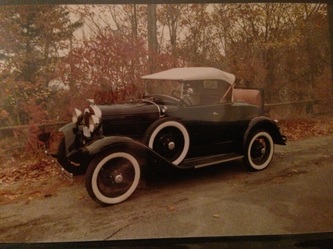

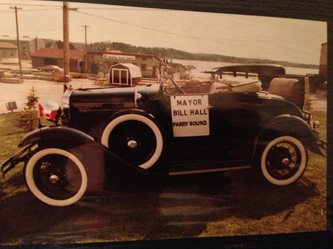

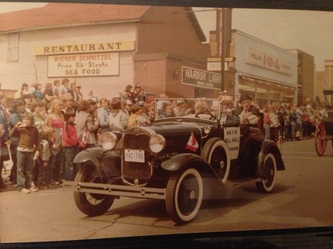

Going through my phone discovered photos that I took last Christmas of when my father Jim, Grandfather and Uncle restored their Model A Fords. Today we have garages to help store and work on our cars. Back then they were restored outside and put away in sheds! Puts things in perspective and nice to know were it all began! These pictures even show my great grandfather! Started the task of working on the engine while I wait for a few parts to complete the front end! I started out by purchasing the Model A engine stand from synders. This mounts to the inlet casting of the block and keeps it sturdy while you rotate the engine 180 degrees. I started by soaking everything in PB Blaster and got to work. First I removed the exhaust manifold then proceeded to remove all the bolts holding the engine pan. I carefully lowered the pan and had to make sure the oil pump didn't drop down and break. I was glad to see the oil pump stayed in the block but the bottom spring was broken and laying in the bottom of the pan. I notice a good amount of sludge in the bottom tray (Typical for an old original engine) but was happy that I didn't see any metal shavings or peices! Next was to remove the valve chamber cover to inspect the valves. Again a good mount of sluge was held in this area. I proceeded to remove the sludge and inspect the valves, lifters, springs and guides. I plugged the 3 holes in the valve chamber so no other sludge or grit went down. Everything looked good. Springs had good tension and no rust or pitting. The next step was to take off the head. I removed all the nuts and most came easy. Only 2 of the studs came out but they will be all replaced with new ones. I made sure to take my time because I didn't want to bust a stud off. I was surprised the head came off easy, usually you have to fight with them to break them loose from the years of water sitting around the head studs. The pistons looked good and so did the walls. Cylinder wall 3 had a small mark in it and I'm going to ask around to see what should be done. All the valve seated properly into the block and all moved up and down as they should. I soaked the valves just to make sure. All the pistons and valves will be cleaned up to make sure all carbon is gone. The valves had the original FORD scripts on them. Next was to remove both side and front timing cover to inspect it for wear. Again I was surprised to see everything was in good condition. No teeth had wear and the timing gear looked to be original because it still had the FORD script on it. The crank had little to no wear on it also. This engine one day will be sent to get a full rebuilt but what I want to do for the time being is clean it up and put all new gaskets in it. Check rear main, center main and front main for adjustment and button it up to see what it will do. The head will be sent to get resurfaced to make sure it's not warped. As I go along with this project I will keep an eye on anything that jumps out at me. Stay tuned! |

RSS Feed

RSS Feed